Oil Tanker with Wind Sails Cuts 5,000 Tons Emissions Annually

Revolutionary Oil Tanker Uses Wind Power to Cut Emissions by 5,000 Tons Annually

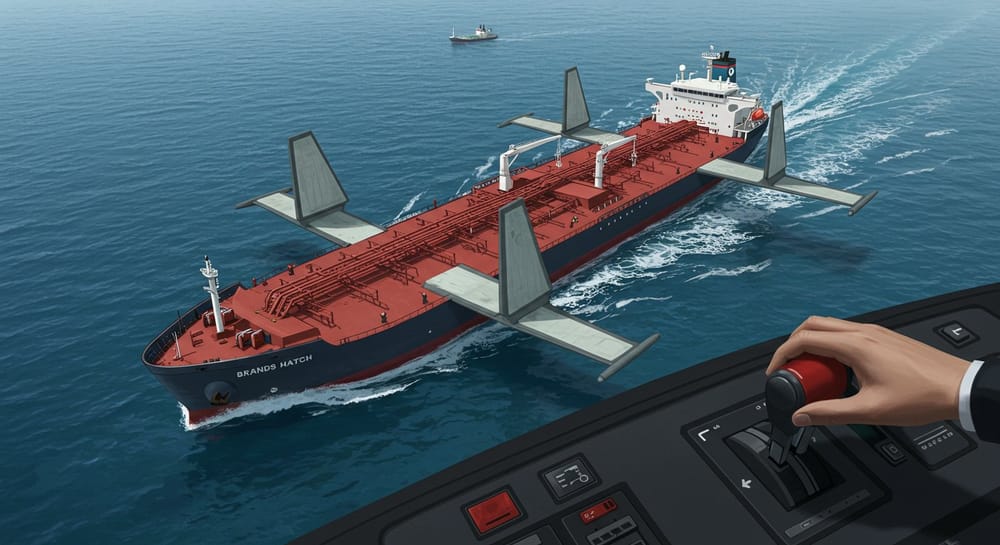

Here's something you don't see every day: a massive oil tanker cruising the ocean with what looks like futuristic sails cutting through the waves. The vessel "Brands Hatch" has captured attention worldwide for combining centuries-old wind power with modern maritime technology, and honestly, it's pretty incredible to watch.

The ship, operated by Union Maritime (a UK company), features innovative "wind wings" developed by Finnish company Norsepower. These aren't your typical canvas sails from pirate movies – they're rigid, adjustable structures that can be positioned to capture wind energy and reduce fuel consumption by up to 15% under ideal conditions.

How Wind-Powered Oil Tankers Actually Work

Now, I know what you're thinking – haven't ships been using wind power for, like, thousands of years? Well, yes and no. These modern wind wings are completely different beasts. They're essentially vertical airfoils that can be adjusted automatically based on wind conditions and the ship's heading.

The technology works by harnessing wind energy to assist the ship's main propulsion system. When conditions are right, the wind wings can provide significant thrust, allowing the engines to work less hard. It's basically a hybrid system for ships – think of it as the maritime equivalent of a hybrid car, but instead of electric motors, we're talking about wind power.

The Numbers Behind the Innovation

Let's break down what 5,000 tons of emissions actually means. To put this in perspective, that's roughly equivalent to taking about 1,000 cars off the road for an entire year. For a single ship, that's actually a pretty significant impact.

According to the technical specifications, the fuel savings range between 12-15% under optimal conditions. That might not sound like much, but when you're talking about massive vessels that consume thousands of gallons of fuel per hour, those percentages add up quickly.

Why This Matters for the Shipping Industry

The shipping industry is under increasing pressure to reduce its environmental footprint. Maritime transport accounts for about 3% of global greenhouse gas emissions, and with international trade continuing to grow, that number isn't going down on its own.

But here's the thing – and this is where it gets interesting – the motivation might not be purely environmental. As one observer pointed out, "I doubt the oil companies give a shit about cutting emissions. They likely did this to cut down on fuel costs." And you know what? That's probably true, but it doesn't make the environmental benefits any less real.

The Technology Behind Wind Wings

These aren't just glorified windmills stuck on a ship. The wind wings use sophisticated sensors and computer systems to automatically adjust their angle and position. They can be rotated, extended, or retracted based on wind conditions, weather, and the ship's route.

The system includes: • Automated positioning controls • Weather monitoring systems • Integration with the ship's navigation • Real-time performance optimization • Emergency retraction capabilities

Global Impact and Future Prospects

While the initial voyage was from China to Singapore, this isn't really a "Chinese" innovation per se. The collaboration involves a UK shipping company, Finnish technology, and international shipping routes – it's basically a global effort to make shipping more sustainable.

The real question is: will this catch on? Early results suggest it might. The combination of fuel cost savings and environmental benefits creates a compelling business case. Plus, with carbon taxes and environmental regulations becoming stricter, technologies like this could become essential rather than optional.

Challenges and Limitations

Of course, it's not all smooth sailing (pun intended). Wind power is inherently variable – sometimes there's too much wind, sometimes not enough, and sometimes it's coming from the wrong direction. The system only works well under specific conditions, which means the 12-15% fuel savings represent the best-case scenario.

There's also the question of maintenance and complexity. Adding any new system to a ship means more things that can potentially break down in the middle of the ocean. However, the technology has been designed with maritime durability in mind.

What This Means for the Future

This development is part of a broader trend toward sustainable shipping solutions. We're seeing experiments with hydrogen fuel cells, electric propulsion for shorter routes, and even solar panels on cargo vessels. The wind wing technology represents one piece of a larger puzzle.

What's particularly encouraging is that this isn't just a prototype or concept – it's an actual working vessel making real commercial voyages. That's a big deal in an industry that's traditionally been pretty conservative about adopting new technologies.

Industry Response and Adoption

The shipping industry has been watching this development closely. While one ship doesn't constitute a revolution, it does prove that the technology works in real-world conditions. Other shipping companies are likely evaluating whether similar systems could work for their fleets.

The key factors for broader adoption will be: • Proven long-term reliability • Clear return on investment • Regulatory incentives • Insurance and safety approval • Scalability to different vessel types

Source Attribution

Source: Originally shared by u/Stannis_Loyalist on r/interestingasfuck

Read the original post: Reddit Thread

Looking Ahead

The Brands Hatch represents more than just a cool piece of technology – it's a glimpse into what the future of shipping might look like. By combining modern engineering with the oldest form of maritime propulsion, we're seeing innovation that's both cutting-edge and beautifully simple.

Will every cargo ship be equipped with wind wings in ten years? Probably not. But will wind-assisted propulsion become a standard option for certain types of vessels and routes? That's starting to look increasingly likely.

The fact that this technology can deliver both environmental benefits and cost savings suggests it has real staying power. And in an industry where margins are tight and environmental regulations are tightening, that combination might be exactly what's needed to drive widespread adoption.